The air inside building or shed becomes very hot and humid without proper ventilation, leading to unhygienic conditions, deterioration in quality of materials stored, lower productivity, restlessness and other undesired effects on workers.

Ventilation is crucial in removing harmful carbon dioxide gas and other unwanted fumes and replacing them with fresh air. Having fresh air in a closed building system is ideal for a good & efficient working environment.

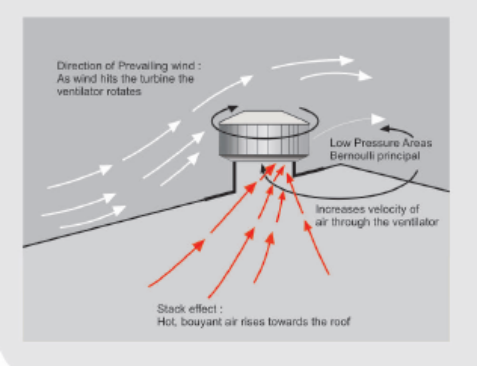

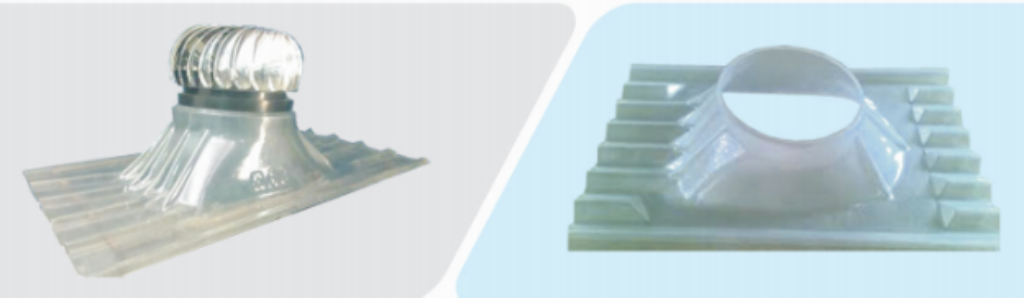

An efficient means to extract warm and stale air through roof mounted Turbo Ventilator, which removes hot gasses fumes bad odor etc., it is light weight, corrosion resistance fitted with the ball bearing and stainless steel, shafts which provides soundless and hassle free operation. Turbo ventilator is a self driven equipment installed on industrial roofs to extract inside air. Turbo ventilators are driven by wind hence no electricity or other power sources are required. As the ventilator is rotated by wind, the stale inside air is exhausted through it and natural inward flow of fresh air is boosted.

Polycarbonate base plates are used to assemble and fix Turbo Ventilators on roofs. We can manufacture these base plates in matching to all roofing profiles according to our clients need. Our Expertise in Roofing Products enables us to design base plates matching with metal sheet precision, thus eliminating the possibility of leakage. Poly carbon base plates can be used for factories, warehouses, Workshops & Industries sheds. Our Turbo Ventilator Polycarbonate Base Plates are manufactured using Vacuum Thermoforming Machines. Only 100% virgin Polycarbonate Resin is used for the manufacture of our premium range of Turbo Ventilator Polycarbonate Base Plate

| Material Used | E-Glass Chopped Strand Matt Thermosetting polyester Resin, Hardener (Mekp - AO - 9%) |

| Profile Design | Customised as per your requirement |

| Length | Standard - 1700 mm ± 10 mm (Can be customised) |

| Throat Diameter | 598 mm ± 5 mm |

| Thickness | 1.5 mm to 2.0mm |

| Weight | 6.2 Kg. ± 0.2 Kg. |

| Material Used | Poly Carbonate Graules (Bayer make) |

| Profile Design | Customised as per your requirement |

| Length Throat Diameter | Standard - 1700 mm ± 10 mm (Can be customised) 598 mm ± 5mm |

| Thickness | 1.5 mm to 2.0 mm |

| Weight | 4.7 Kg ± 0.2 Kg. |

| Vantilator Vanes | 0.50 mm Industrial Hi-Grade Aluminum (Hindalco) |

| Ventilator Top Plate | Stainless Steel (0.50 mm) |

| Ventilator Bottom of Ring | Stainless Stell (0.50 mm) |

| Weight of Ventilator | 6.5 Kg ± 0.2 Kg |

| Height of Ventilator | 410 mm ± 5mm |

| Center Width of Ventilator | 735 mm ± 5 mm |

| Dia of Top Plate | 500 mm ± 5mm |

| Dia of Bottom Ring | 600 mm ± 15 mm |

| Nos of Vanes | 42 Nos Die Pressed |

| Thicness of Vanes | 0.50 mm ± 0.02 mm |

| Nos of Bearing | 6001 ZZ Permanently Lubricated & Sealed |

| Rivets | Alumium Alloy with Washer |

| Packing Box | 3/5 Ply, 750 x 750 x 425 mm Appox |

- Type - Roof and wall panel

- Length - As per requirement

- Thickness - 30 mm to 150 mm

- Density - 40 kg /cu. mtr.

- Globally proven technology - can be Installed on all kinds of roofs

- Zero running cost since it operates on wind without electricity

- Wind driven ventilators work 24 x 7

- Aluminium structure is durable & no maintenance required

- Safe & hazard free from fire &short circuit / electrical shocks

- Aerofoil Blades to deflect water and dust

- Dynamically balanced for frictionless rotation at low wind velocity

- Transparent base plates provide natural light during day time, thus reducing lighting load

- Totally weatherproof

- Available in 24" diameter size with PP base ring and SS cap

- Increases productivity by promoting healthier and hygienic air environment through proper ventilation

- Improving the working shop floor conditions naturally

- By reducing the lighting load due to the use of daylight

- Reducing the exhaust fans load

- Reducing the replacement & maintenance cost of lights & exhaust fans

- Get accelerated depreciation as its an energy saving device driven by wind

- Improved working environment and aesthetics by dynamically moving devices

- Attractive aesthetic to the building and also environmental friendly may qualify for carbon credits, Turbo Ventilator Manufacturer – Ventilator Manufacturers.

The turbo ventilator operates by utilizing the velocity of the wind to induce air flow by centrifugal action. The centrifugal force caused by the spinning vanes creates a region of low pressure area which draws air out through the vanes. Air drawn out by the vanes is continuously replaced by fresh air from the outside. The slightest breeze will cause the turbine to spin and even after the breeze has stopped, the flywheel effect of the rotor cage will use its stored energy to continuously remove air giving rise to ventilation. Suction is maintained even at low wind velocities.

- Industries

- Godowns

- No electricity charges

- No hazards like short circuits

- Ware houses

- Factory

- Power house