We offer different types of sandwhiched panels i.e. PUF (Polyurathene Foam), Rock wool, Glasswool, XLPE etc. Most commonely used panels are PUF insulated and details are as below.

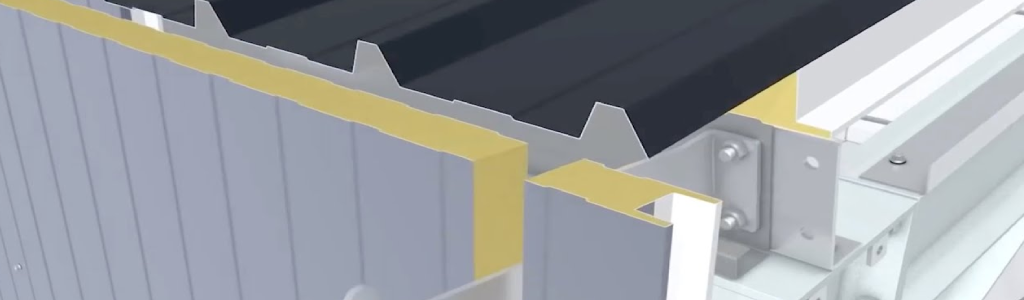

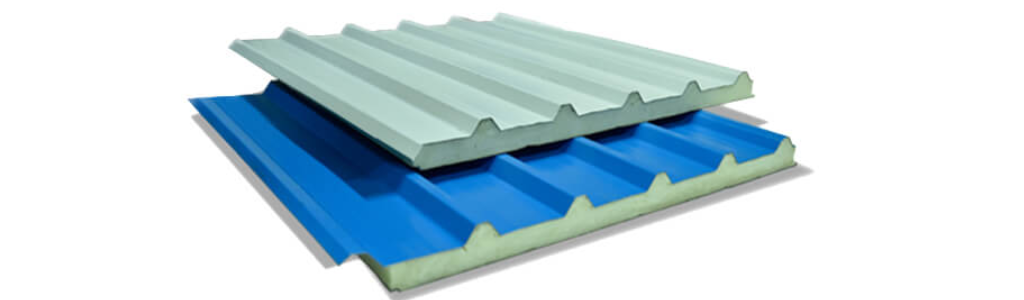

These sandwich panels are filled with polyurethane in the core achieving Good R-values and consist of exterior and interior facings of relatively thin Profiled metal sheets.

Sandwich elements have become essential in the construction industry. They are used alongside traditional building materials such as wood, steel, and concrete and have become the first choice material for the realization of various buildings such as Production Halls, Airports, Exhibition Halls, Cold Rooms, Plants, Cold Storages, Auditoriums and many others. The reasons for this trend are to be found in their excellent properties as insulating elements. Architects select these multilayer panels for many reasons, including their design potential and aesthetic, and their static and acoustic properties.

Polyurethane sandwich puff panel comes complete with specially formed tongue-and-groove joints ensuring a perfect fit and maximum integrity, Assembly is fast, easy and cost-effective .

|

Panel thickness available : |

30mm, 40mm, 50mm, 60mm, 80mm, 100mm, 120mm |

||||

|

Panel width available : |

1060mm |

||||

|

Panel length available : |

2000mm-12000mm |

||||

|

Average density : |

40± 2kg/m |

||||

|

Thermal conductivity : |

0.024-0.03 W/m |

||||

|

Temperature range : |

-40+800C |

||||

|

Free from CFC : |

CFC free |

||||

|

Type of foam : |

B1, B2, B3, PIR |

||||

|

Heat transfer co-efficient : |

-0.022W/M2*k |

||||

|

Pressure : |

0.10Mpa |

||||

|

Cubic Area Change : : |

1%(-30 C – 100 C/96h) |

||||

|

Polyester primer : |

5 micron Non-toxic food-graded STANDARD polyester finish paint. |

||||

|

RAL 9010 color : |

20 micron |

||||

|

Back coat : |

5 micron |

||||

|

Resistance to saline mist : |

5 micron |

||||

|

>500h (ECCA TB) : |

100 h (ASTM D 2247) |

||||

|

Wall |

Roof |

||||||||

|

Width |

1000 mm |

1000 mm |

|||||||

|

Length |

12000 mm |

12000 mm |

|||||||

- Energy-efficient and durable Panels.

- Tongue and groove type joinery system.

- Space saving Various designs.

- vivid colours.

- Energy conservation as per ECBC code.

- Suitable for diverse applications

- Can withstand wind velocity up to Maximum Level.

- Can withstand heavy snowfall/rainfall.

- It can withstand extreme temperature from -50 degree Celsius to +50 degree Celsius.

- PUF having a thermal conductivity of 0.018 kCal prevents cross heat flow between room & outside ambiance.

- Easy to Install with Screw down system for aesthetic appeal

- These shelters are very light in weight, compact and have high structural strength thereby making it possible to create suitable size.

- No air or water can penetrate through the panels of the shelter.