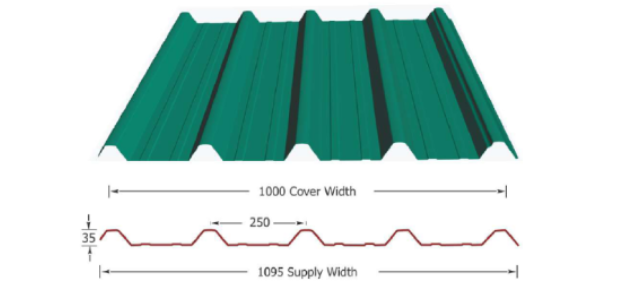

Colour coated Metal Roofing sheets have been used extensively by the construction industry throughout the world for nearly two decades because of its excellent corrosion resistance, aesthetic look, durability, wide ranges of colours. It has become the preferred material for a wide range of construction uses, particularly for roofing and cladding. Large crest with two parallel mini ribs between the crest makes the profile stronger which translates into long spanning capabilities. Thus the profile is most recommended for heavy rainfall intensity area.

Pre-Painted Galvanized Iron (PPGI)

|

Thickness (TCT) |

0.30 mm – 0.80 mm |

||||

|

Metallic Coating |

99.5% ZN as per IS 277, Colour as per IS 14246, Z-120Gsm Colour. |

||||

|

Tensile Strength |

240-550 MPa |

||||

|

Paint Coating |

RMP/SMP/PVDF |

||||

|

Paint Thickness |

18-22 micron on Top & 5- 8 micron on bottom. |

||||

|

Thickness Tolerance (+/- 02) |

As per IS 513 for base metal |

||||

|

Standard followed |

IS 14246 / 277 |

||||

Pre-Painted Galvalume (PPGL)

|

Thickness (TCT) |

0.30 mm – 0.80 mm |

||||

|

Metallic Coating |

Zinc–Aluminium Alloy Coating, 55.5% AL, 43.5% ZN, 1.5% SI as per ASTM 792M, AS1397:1993, IS 15965:2012 AZ-150Gsm Colour. |

||||

|

Tensile Strength |

340-550 MPa |

||||

|

Paint Coating |

RMP/SMP/PVDF |

||||

|

Paint Thickness |

18-22 micron on Top & 5- 8 micron on bottom. |

||||

|

Thickness Tolerance (+/- 02) |

As per IS 513 for base metal |

||||

|

Standard followed |

ASTM1397A / A792 / A755 |

||||